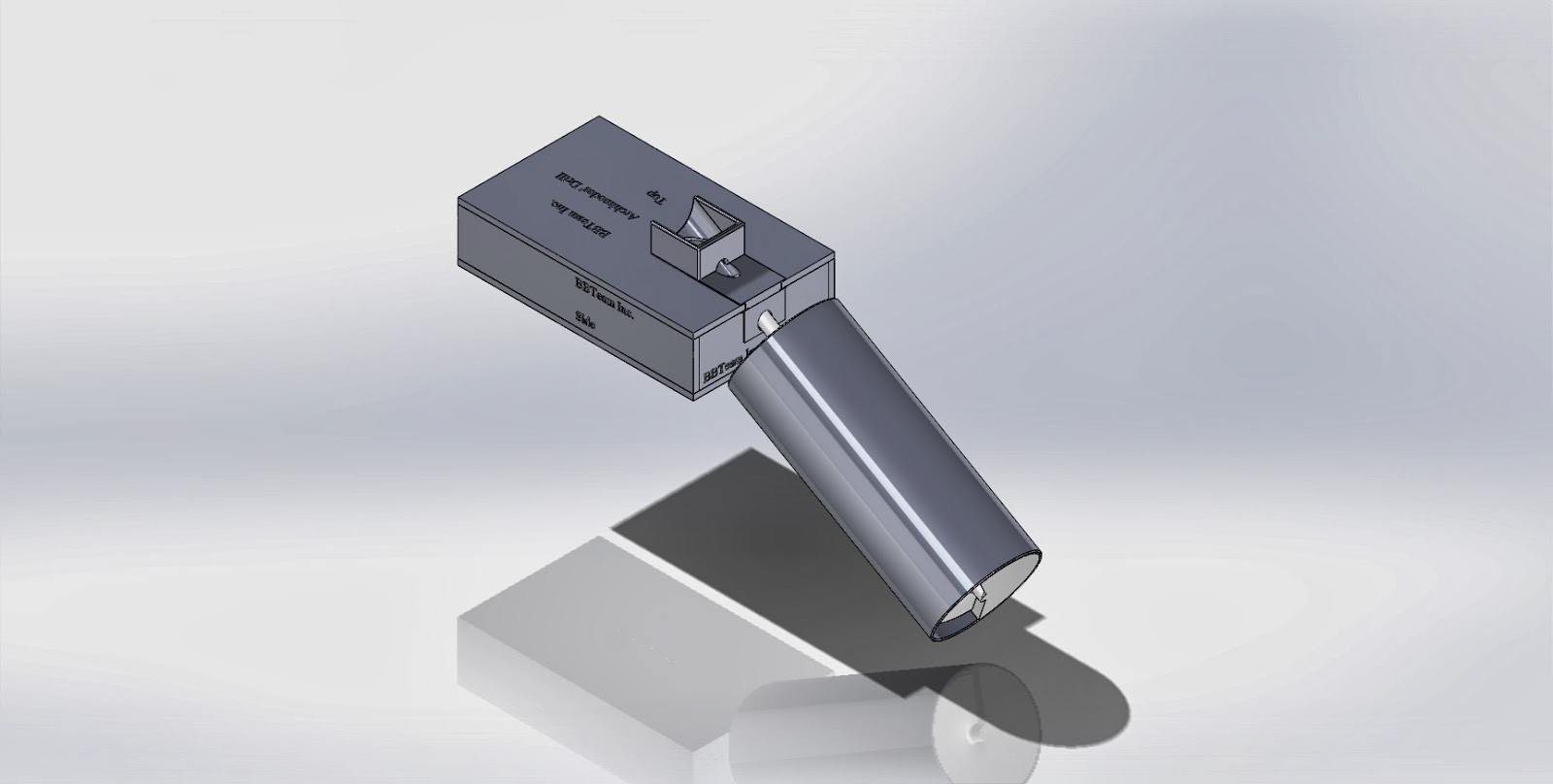

We were able to get the code and circuit set up with the Arduino board and everything seemed to function as planned. It did seem however that the board was not able to supply sufficient power to both the DC and servo motors, as the DC ran much slower than it did without the servo attached.

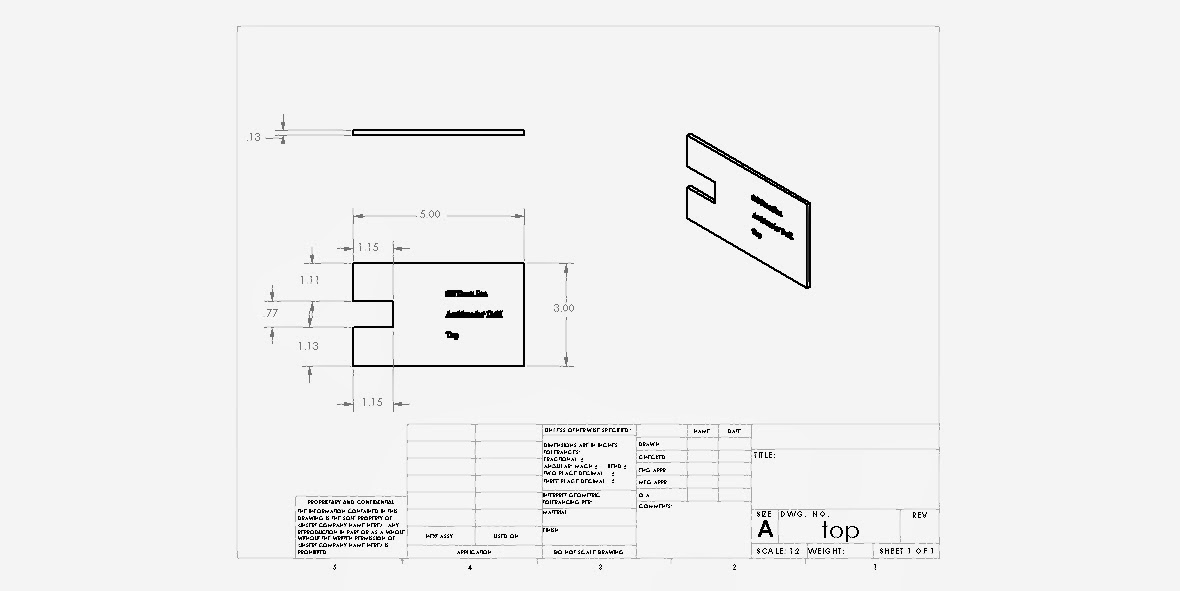

We received the two printed pieces designed to be slid into the top and front sections of the base, as well as the old DC housing design. We did not get the screw housing or the new DC housing, both of which were critical parts to actually make our design function. As far as laser cut parts we only received one side piece and the bottom piece, so we were unable to construct the base.

This week all group members met and spent approximately 3 hours working on the project.

.JPG)

+drawing.JPG)

.JPG)

+drwing.JPG)